-

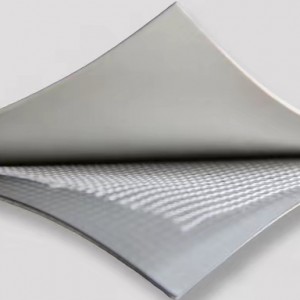

TPO Reinforced Membrane -One Stop Solution

1.A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE Geotextle.

2.All type of membranes,including reinforced, back fleece, sand coated , self adhesive ,walkway board.

3.All accessories are available ,including prefabricated, sealing and fasteners.

4.No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service etc.

-

Newest -TPO Walkway Board

● Type : TPO Walkway , PVC Walkway

● Thickness : 3.0mm -4.5mm or customized

● Width: 800-870mm or Customized

● Color: White/Grey/Black(or customized

-

TPO Fleece Backing Benifits

1.A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE Geotextile.

2.All type of membranes,including reinforced, back fleece, sand coated , self adhesive ,walkway board.

3.All accessories are available ,including prefabricated, sealing and fasteners.

4.No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service etc.

-

TPO- Self Adhesive Benifits

◆ FREE SAMPLE for quality and performance checking

◆ LONG guarantee period , no worries about quality &services

◆ Able to compete with other suppliers on pricing

◆ OEM &customized requests are acceptable and welcomed

◆ Strong capacity &fast delivery

◆ Compliance with international standards

-

One Stop Solution -PVC-Reinforced Membranes

One Stop Solution

◆ A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE Geotextile.etc.

◆ All type of membranes,including reinforced, back fleece, sand coated , self adhesive ,walkway board.etc.

◆ All accessories are available ,including prefabricated, sealing and fasteners.

◆ No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service .etc.

-

NEWEST PVC Walkway Roll

One Stop Solution

◆ A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE, Geotextile.etc.

◆ All type of membranes,including walkway board,reinforced,back fleece, sand coated , self adhesive ,walkway board.etc.

◆ All accessories are available ,including prefabricated, sealing and fasteners.

◆ No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service .etc.

-

NEWEST Design-PVC Walkway Board

One Stop Solution

◆ A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE, Geotextile.etc.

◆ All type of membranes,including walkway board,reinforced,back fleece, sand coated , self adhesive ,walkway board.etc.

◆ All accessories are available ,including prefabricated, sealing and fasteners.

◆ No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service .etc.

-

PVC Fleece Backing Membranes

One Stop Solution

◆ A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE Geotextile.etc.

◆ All type of membranes,including reinforced, back fleece, sand coated , self adhesive ,walkway board.etc.

◆ All accessories are available ,including prefabricated, sealing and fasteners.

◆ No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service .etc.

-

PVC Self Adhesive Membranes Solutions

One Stop Solution

◆ A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE Geotextile.etc.

◆ All type of membranes,including reinforced, back fleece, sand coated , self adhesive ,walkway board.etc.

◆ All accessories are available ,including prefabricated, sealing and fasteners.

◆ No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service .etc.

-

NEWEST TPO Walkway Board Solution

One Stop Solution

◆ A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE, Geotextile.etc.

◆ All type of membranes,including walkway board,reinforced,back fleece, sand coated , self adhesive ,walkway board.etc.

◆ All accessories are available ,including prefabricated, sealing and fasteners.

◆ No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service .etc.

-

EPDM roof membranes Solutions

◆ A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE Geotextile.etc.

◆ All type of membranes,including reinforced, back fleece, sand coated , self adhesive ,walkway board.etc.

◆ All accessories are available ,including prefabricated, sealing and fasteners.

◆ No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service .etc.

-

One Stop Solution- EPDM Pond liner

◆ A full range of products categories,including TPO, PVC EPDM,EVA ,HDPE Geotextile.etc.

◆ All type of membranes,including reinforced, back fleece, sand coated , self adhesive ,walkway board.etc.

◆ All accessories are available ,including prefabricated, sealing and fasteners.

◆ No worries for every single point at quality , pricing , package, shipment, delivery, guarantee,service .etc.